How To Identify Asbestos

A key aspect of a safe and complete asbestos risk assessment is the inclusion of a hazardous substance risk assessment form. This is not something that should be taken lightly as asbestos in homes is a real risk in any property built before 1990. Therefore knowing how to identify asbestos is a critical step in any type of asbestos training.

But this can be an expensive option. If you wish to test any material you suspect of containing asbestos, you can contact the National Association of testing Authorities for an independent evaluation. With over 3000 asbestos containing products used in construction prior to 1990, professional consultation and testing is the safest option for the identification of this highly hazardous material. But there are several common characteristics of asbestos containing materials.

Warning signs: look for any warning signs or labels that indicate the existence of asbestos.

Age: any property built before the late 1980’s could contain asbestos. Consult with local authorities, the structure’s builder, previous owners and neighbours.

Fasteners and joints: check the battens used to to cover the joints between sheets of asbestos containing materials like AC sheeting. Any broken battens, gaps in joiners or loose nails, can indicate the presence of asbestos.

Close inspection: if you have a digital camera with a macro mode function, use it to take a close up photo of the material. Asbestos fibres are microscopic but the strands that are made up of these fibres can often be found clumped together (see left image for example). Note: never break the material apart to check as it could release asbestos fibres into the immediate area.

It must be noted that these are initial steps and cannot guarantee the total identification of all asbestos materials. For that, an accredited asbestos specialist will need to be engaged.

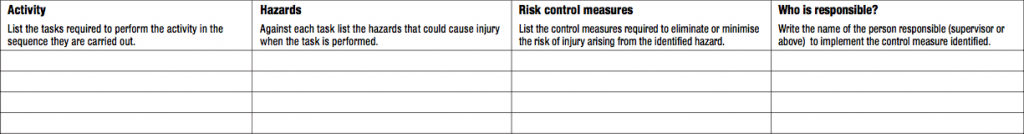

Keeping up with technological advancements in the field of hazard and risk management is tiresome and at times just too much of a hassle. But turning a blind eye to developments in the risk analysis process will come at cost to business productivity and even worker safety.

Keeping up with technological advancements in the field of hazard and risk management is tiresome and at times just too much of a hassle. But turning a blind eye to developments in the risk analysis process will come at cost to business productivity and even worker safety.