Why Are Risk Assessments Carried Out On Paper?

Back in the good old days the various stages of risk assessment involved turning up to work and not getting hurt. It was a simpler risk assessment system but suffice to say it didn’t do a lot for safe operating procedures.

We joke about it now but this history of poor workplace health and safety practices highlights the importance of a risk assessment. Paper-based risk assessments have helped keep workers save for decades but now in the digital age, they are quickly becoming redundant. New software alternatives are quicker to complete and easier to administer, which begs the question: why are risk assessments carried out on paper?

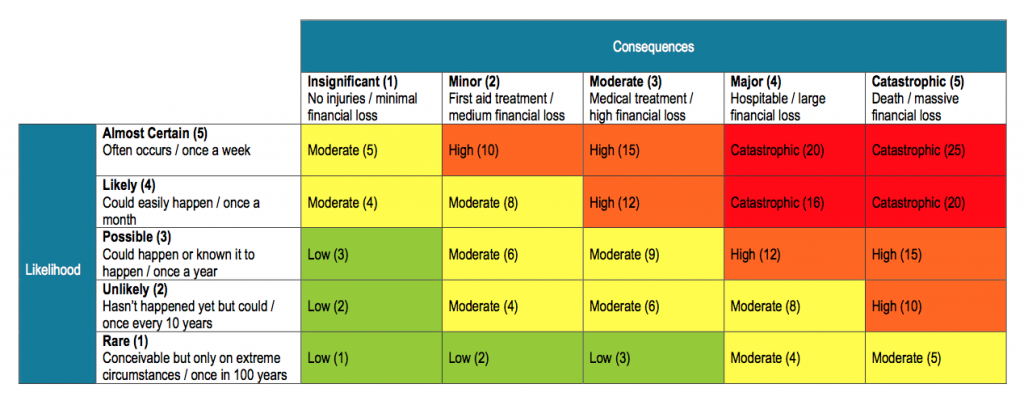

The simple answer is because it used to be the easiest way of carrying out a risk assessment. That isn’t to say writing risk assessments on paper is still the easiest way to do things. The table-based risk assessment layout works well for paper but now with risk assessment software development extending well into the construction industry, it’s become clear that the future of risk assessment is found in technology.

You can find out more about construction risk assessment software here. For more useful tips and information, check out the SafeWorkPro Blog.