How a Simple Process Drives Safety Compliance

Safety management systems have come a long way in the last 250 years. Just think back to workplace conditions during the Industrial Revolution – almost no pay, child labour, very long hours, and extremely dangerous work conditions with exposure to chemicals, accident-prone machinery, and no WHS requirements whatsoever.

But this has changed over the years. Legal reforms and acts were introduced – the Factory Act, the Employer’s Liability Act, and finally, the 1974 Health and Safety at Work Act. This legal document became the foundation for workplace health and safety processes in the UK and the rest of the world. And it led to the increasingly more complex safety processes we have today.

The core purpose of WHS is to keep people safe. Simple. With the increasing complexity of requirements and standards, Business owners, project managers and safety officers alike have to be careful of falling into the trap of using compliance to document requirements like the SWMS as their main measure of WHS compliance. This article looks at why adhering to document requirements is a poor standalone indicator of compliance. We also suggest how a simple safety process drives the success of your WHS compliance.

Documents are Symbols of a Process

Safety isn’t symbolic. It is real and should be treated in the real world, not on a document. Safety management systems do involve documents, but they symbolise a process. For example, a SWMS is a safety planning tool that identifies the risks of high risk construction work and the actions taken to manage those risks. It symbolises the process you are going to take when dealing with the risks and making sure your workplace and its workers are safe from those risks. When it’s under the (judges) hammer, the process symbolised (documented) matters most – not the symbol or the document itself.

Downloading a generic template for your SWMS, JSA, or any other safety document is like taking the symbol without taking the process it represents. And that defeats the whole point of your safety management system and its documents. To comply with WHS requirements, you should be focusing on the processes required to keep your workplace and its workers safe – not just on the documents themselves.

WHS audits look at whether you have followed an effective process that actively reduces the risks in your workplace. They care about if you have actually provided a safe work environment. Not simply whether you have ticked the box of completing a piece of paperwork.

In 2013, The Supreme Court Qld in a case against a QLD construction company for the death of two workers cited:

“work practices focused too much on the work performed onsite and did not pay adequate attention to the dangers presented by the conditions of the site itself”

In other words, not considering risks on the ground, in the real world can have significant impacts when taken to the extremes. Focussing too hard on the details of the tasks to be completed can lead to ignoring all the risks that are actively present

What you focus on matters. And if you want to pass your WHS audit and actually keep your workers safe, then it’s time to focus on the safety management process behind the symbols and documents.

But I still go through a process when filling in a template?

Safety management systems aren’t just about the symbols. They’re about the processes behind them. But you may be wondering – isn’t downloading a generic template still technically a process? Sure. But think about this. What process is more effective at satisfying the Work Health and Safety Act requirement to provide a safe work environment? Is it:

- Find a generic SWMS template on Google, Officeworks or other source

- Complete the boxes provided by the template as best as you can

- Gather up or seek out workers individually and gather signatures

- Store it onsite until the work is done

- Transferring the document to a folder in your office when you are done with the site

Or:

- Identify a the risks onsite, in person

- Build a new SWMS or modify the existing version to cover all task & site-specific risks that are present. Pushed to everyone to sign.

- Monitor how measures are being implemented while work is being completed with real time automated risk rating notifications

- Review by anyone relevant once the work has been completed

- Automatic document storage once complete for any future audits, follow-ups, or learning

From a legal standpoint, the second option is better,

The very purpose of developing a SWMS is to ensure that employers and workers have taken the time to identify the high-risk tasks to be done on site. And then, it is to develop measures to manage these risks and tasks in the context of the work being done. The very nature of a SWMS is that it is specific. It is created specifically in response to a specific site, specific tasks, and specific risks. A generic templated SWMS will not meet the intention behind WHS requirements. Instead, it will defeat the real power of the SWMS and even take away from your safety management.

As WorkSafe Victoria explains, “our concern is not what is written but what actually happens”. A generic SWMS is a symbol of safety that only provides guidance. To focus on the process and comply with WHS requirements, your SWMS and other safety documents need to be customised. It is the second process that is more likely to pass a WHS audit because it demonstrates an active approach to creating a safe work environment. And it is the first process that will get a much more severe punishment when a safety incident does happen, even though both processes are represented by the same type of document.

How to Prioritize the Process

The simplest way to boost the effectiveness of your safety process is to use a digital safety platform like SafeWorkPro. While you can do your safety management physically or digitally, doing it digitally is what will make the difference. Why?

Safety management software simplifies your safety management. Turning a complex process into a simple, easy to understand workflow that allows for an easier way to assess, mitigate, monitor and review workplace risks of all nature. It makes sure that your safety management system is customised, comprehensive, and lets you focus on the process. Leave the document creation, distribution and storage to the software. With safety management software, you can seamlessly customise, prioritise, and ensure your safety management system and its processes exceed WHS regulations.

SafeWorkPro is the Australian safety management software that can make sure your workplace prioritises the process over the symbols.

- Customise your SWMS, JSA, or other safety documents specifically to your worksite using our flexible document builder

- Make sure your specific workplace risks are managed and your workers are safe

- Ensure your company truly complies with WHS requirements

Do all of this seamlessly and in one place with the SafeWorkPro platform. Click the button below to find out more.

More From The SafeWorkPro Blog

Safety Rule This Summer: Under the hot summer sun, make safety priority number one

HEAT AND SUN SAFETY PLAN(5’S OF SUN SAFETY) Ultra-violet (UV) rays are deadly, so sun safety is vital in Queensland where the UV Index is three or above all year round. Outdoor workers must be supplied with sun protective clothing including a hat, sunscreen and sunglasses. You can also look at the possibility of rotating […]

Hazard management and risk assessment: what’s the difference?

They both sound like they mean the same thing but there is a difference between a risk and a hazard. Understanding this difference is an aspect of health and safety information that is all too often overlooked by workers and managers alike. In the field of occupational health and safety, this is but one of many basic risk assessment questions.

There is a difference and it is an important element to most hazard and risk assessment procedures. Based on Workplace Health and Safety Queensland’s codes of practice, the below definitions of risk and hazard are applicable to all Australian jurisdictions.

A hazard is a “situation or thing that has the potential to harm a person.” These can be aspects to a workplace like machinery, tools, vehicles or chemicals. Alternatively a hazard could include certain elements to a workplace like the repetitiveness of a job, bullying or violence.

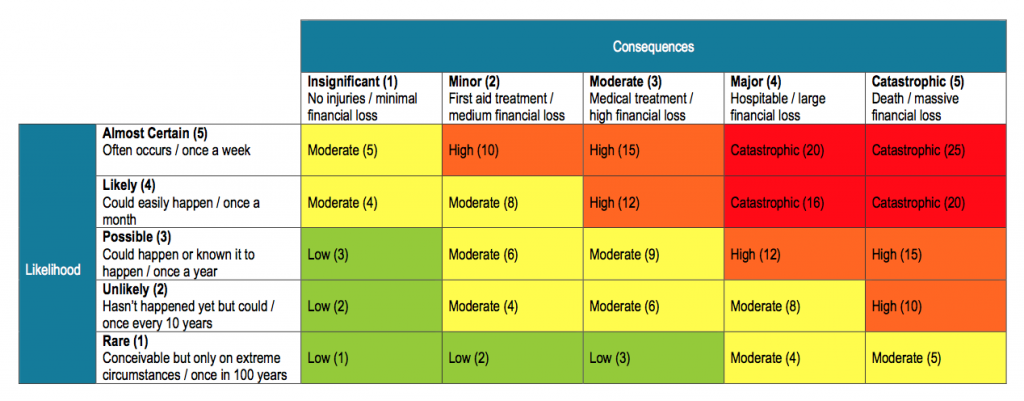

A risk is the likelihood of a person getting harmed (death, injury or illness) if they are exposed to a hazard. For construction workers, the level of risk associated with a hazard is determined by the completion of a risk assessment matrix (see image below).

Understanding the difference is obviously important in getting hazard and risk identification right in the workplace but it is also crucial for writing risk assessments. Risk control methods are based on accurate risk reporting and hazard identification meaning if done inconsistently, then the well being of workers is unnecessarily insecure.

High Risk Construction Work

Not all building projects require a hazard risk analysis. In fact according to Safe Work Australia, construction activities must equal or exceed a cost of $250 000 to be legally defined as a construction project. Nonetheless any worksite that involves a specific type of high risk construction work must comply with OHS legislation Australia, or more specifically the Work Health and Safety Act. This means risk assessments.

OHS Legislation Australia

This legislation can be difficult to understand, with a range of varying regulators and government bodies having their own requirements for the completion of a construction method statement. Nonetheless the risks in construction remain the same no matter where the work is being undertaken. Safe Work Australia’s codes of practice outlines various types of high risk construction work and the methods of risk identification.

Safe Operating Procedures

Safe Work Australia’s codes of practice outline what the PCBU (persons conducting a business or undertaking) is required to do in order to conduct safe operating procedures regardless of the nature of the construction work. Under national work health and safety regulation 297, the PCBU is required to:

• Identify possible hazards that, within reason, could increase risk

• Eliminate the risk to the extent that is possible

• If total elimination is not possible, then minimise the risk through the implementation of control measures

• Maintain control measures through continued reviews and revision so far as it is possible, to ensure the worksite remains compliant with WHS regulations

Enforcement Options

Safe Work Australia has compiled a list of the required licenses workers must attain before undertaking any of these high risk jobs. Without doing so both the worker and the PCBU risk punitive measures from the related regulator.

Completing the required paperwork and attaining the appropriate licenses is vital to ensuring your business does not feel sting of the regulators. Safe Work Australia provides the model of regulation and codes of practice that form the basis of safe work method statements (SWMS) however it is not a regulator itself. Each state has it’s own government regulator but because they’re based on the same framework established under Safe work Australia, their powers and responsibilities are somewhat similar. For example, unlike many other states, there is no Work Safe QLD but instead Workplace Health and Safety Queensland (WHSQ) is the central regulatory authority. WHSQ’s role includes licensing and registrations, industry consultation, reviewing relevant laws as well as the enforcement of a hazard and risk management procedure in the workplace. Their compliance and enforcement options are broad and include:

• Workplace inspections and compliance requests

• A variety of notices including prohibition, improvement, non-disturbance, electrical safety protection and unsafe equipment

• On the spot fines ranging from $600 000/five years jail for PCBUs who have committed category one breaches (risk of serious injury or death) to $100 000 for category three breaches (failure to comply with notices)

• Seizure of equipment of substances

• Suspension or cancellation of license or accreditation

• Enforceable undertakings (legally binding agreements)

To reiterate: each state or jurisdiction has different regulators but the above enforcement options available to WHSQ are commonplace in other regulatory authorities. For more information Safe Work Australia has developed a thorough code of practice that systematically explains the WHS regulations.