How a Simple Process Drives Safety Compliance

Safety management systems have come a long way in the last 250 years. Just think back to workplace conditions during the Industrial Revolution – almost no pay, child labour, very long hours, and extremely dangerous work conditions with exposure to chemicals, accident-prone machinery, and no WHS requirements whatsoever.

But this has changed over the years. Legal reforms and acts were introduced – the Factory Act, the Employer’s Liability Act, and finally, the 1974 Health and Safety at Work Act. This legal document became the foundation for workplace health and safety processes in the UK and the rest of the world. And it led to the increasingly more complex safety processes we have today.

The core purpose of WHS is to keep people safe. Simple. With the increasing complexity of requirements and standards, Business owners, project managers and safety officers alike have to be careful of falling into the trap of using compliance to document requirements like the SWMS as their main measure of WHS compliance. This article looks at why adhering to document requirements is a poor standalone indicator of compliance. We also suggest how a simple safety process drives the success of your WHS compliance.

Documents are Symbols of a Process

Safety isn’t symbolic. It is real and should be treated in the real world, not on a document. Safety management systems do involve documents, but they symbolise a process. For example, a SWMS is a safety planning tool that identifies the risks of high risk construction work and the actions taken to manage those risks. It symbolises the process you are going to take when dealing with the risks and making sure your workplace and its workers are safe from those risks. When it’s under the (judges) hammer, the process symbolised (documented) matters most – not the symbol or the document itself.

Downloading a generic template for your SWMS, JSA, or any other safety document is like taking the symbol without taking the process it represents. And that defeats the whole point of your safety management system and its documents. To comply with WHS requirements, you should be focusing on the processes required to keep your workplace and its workers safe – not just on the documents themselves.

WHS audits look at whether you have followed an effective process that actively reduces the risks in your workplace. They care about if you have actually provided a safe work environment. Not simply whether you have ticked the box of completing a piece of paperwork.

In 2013, The Supreme Court Qld in a case against a QLD construction company for the death of two workers cited:

“work practices focused too much on the work performed onsite and did not pay adequate attention to the dangers presented by the conditions of the site itself”

In other words, not considering risks on the ground, in the real world can have significant impacts when taken to the extremes. Focussing too hard on the details of the tasks to be completed can lead to ignoring all the risks that are actively present

What you focus on matters. And if you want to pass your WHS audit and actually keep your workers safe, then it’s time to focus on the safety management process behind the symbols and documents.

But I still go through a process when filling in a template?

Safety management systems aren’t just about the symbols. They’re about the processes behind them. But you may be wondering – isn’t downloading a generic template still technically a process? Sure. But think about this. What process is more effective at satisfying the Work Health and Safety Act requirement to provide a safe work environment? Is it:

- Find a generic SWMS template on Google, Officeworks or other source

- Complete the boxes provided by the template as best as you can

- Gather up or seek out workers individually and gather signatures

- Store it onsite until the work is done

- Transferring the document to a folder in your office when you are done with the site

Or:

- Identify a the risks onsite, in person

- Build a new SWMS or modify the existing version to cover all task & site-specific risks that are present. Pushed to everyone to sign.

- Monitor how measures are being implemented while work is being completed with real time automated risk rating notifications

- Review by anyone relevant once the work has been completed

- Automatic document storage once complete for any future audits, follow-ups, or learning

From a legal standpoint, the second option is better,

The very purpose of developing a SWMS is to ensure that employers and workers have taken the time to identify the high-risk tasks to be done on site. And then, it is to develop measures to manage these risks and tasks in the context of the work being done. The very nature of a SWMS is that it is specific. It is created specifically in response to a specific site, specific tasks, and specific risks. A generic templated SWMS will not meet the intention behind WHS requirements. Instead, it will defeat the real power of the SWMS and even take away from your safety management.

As WorkSafe Victoria explains, “our concern is not what is written but what actually happens”. A generic SWMS is a symbol of safety that only provides guidance. To focus on the process and comply with WHS requirements, your SWMS and other safety documents need to be customised. It is the second process that is more likely to pass a WHS audit because it demonstrates an active approach to creating a safe work environment. And it is the first process that will get a much more severe punishment when a safety incident does happen, even though both processes are represented by the same type of document.

How to Prioritize the Process

The simplest way to boost the effectiveness of your safety process is to use a digital safety platform like SafeWorkPro. While you can do your safety management physically or digitally, doing it digitally is what will make the difference. Why?

Safety management software simplifies your safety management. Turning a complex process into a simple, easy to understand workflow that allows for an easier way to assess, mitigate, monitor and review workplace risks of all nature. It makes sure that your safety management system is customised, comprehensive, and lets you focus on the process. Leave the document creation, distribution and storage to the software. With safety management software, you can seamlessly customise, prioritise, and ensure your safety management system and its processes exceed WHS regulations.

SafeWorkPro is the Australian safety management software that can make sure your workplace prioritises the process over the symbols.

- Customise your SWMS, JSA, or other safety documents specifically to your worksite using our flexible document builder

- Make sure your specific workplace risks are managed and your workers are safe

- Ensure your company truly complies with WHS requirements

Do all of this seamlessly and in one place with the SafeWorkPro platform. Click the button below to find out more.

More From The SafeWorkPro Blog

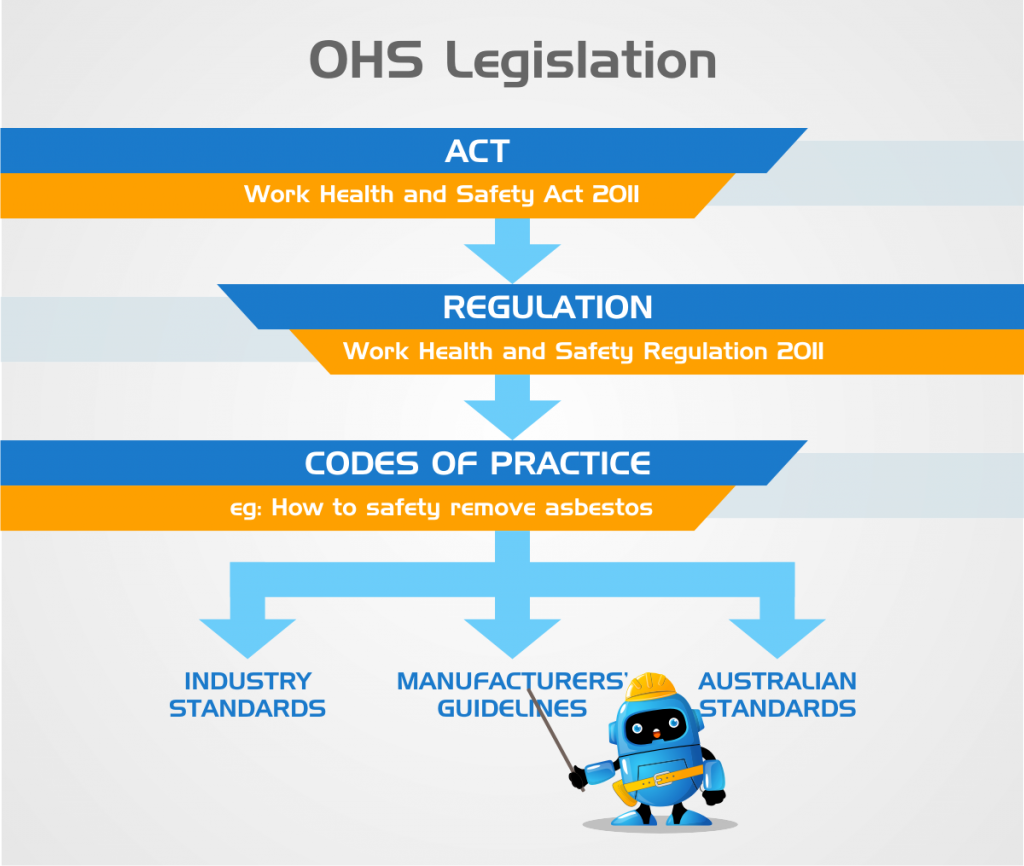

OHS Legislation Explained

Interpreting complicated occupational health and safety laws is a hassle that many small and large businesses struggle to find time for. This presents issues because with a range of various penalties and regulations at stake, compliance with safety laws in the workplace is not to be trifled with.

OHS legislation Australia is made up of several different layers, each with its own detail and level of obligation. Understanding this hierarchy is important for not only avoiding preventable safety incidents but also for establishing and maintaining high workplace OHS standards.

The Work Health and Safety Act 2011

The WHS Act defines the roles and obligations that duty holders must comply with. OHS policies and procedures outlined under the Act are legally enforceable and violations of them could result in significant penalties. Every Australian jurisdiction (state or territory) has different regulators but for a broad idea of what enforcement options are available to them, read about Workplace Health and Safety Queensland.

Occupational Health and Safety Regulations

The Work Health and Safety Regulation 2011 supports the WHS Act in more detail. The Act is full of terminology that can be difficult to understand so the regulation works as a more detailed explanation of OHS policy. Specifically, the WHS regulation provides details on methods of compliance, hazard control and other certain obligations in relation to these. Like the Act, WHS regulations must be complied with or strict penalties can be applied.

Codes of Practice

As part of the policy goal of harmonised workplace health and safety laws, Safe Work Australia has published model codes of practice for a variety of high risk construction work. Unlike the WHS Act and regulations, the codes of practice are not legally binding but serve as practical guides for achieving the OHS standards established under the Act. This means that duty holders are not legally required to follow any of the guidelines. However, unless there is another method of controlling risk to an equal degree, it is strongly recommended that duty holders follow the practical guidance offered in the codes of practice. The codes outline safe work practices for a variety of high risk work. For a full list, check out Safe Work Australia’s model codes of practice.

National Health and Safety Standards

This refers to the work practices and benchmarks set out in peak industry standards, as well as manufacturer guidelines. On top of broad national standards, these aim to provide guidance material to a person conducting a business or undertaking (PCBU) who wishes to demonstrate due diligence in eliminating or reducing workplace risk. The guidance material outlined in these standards has no legal status meaning recommendations are not enforceable or mandatory (unless specifically referred to in the WHS legislation).

The hierarchy of Australian OHS legislation sets out the legal obligations PCBU’s must abide by as well as the practical guides for resolving workplace health and safety issues. For more information on health and safety laws and risk assessment procedures, read the SafeWorkPro Blog.

Free SWMS Template

Are you looking for a free SWMS template? We got you. You can download one on our resources page. This is the template that is found on page 42 of the Construction Work Code of Practice that was published by Safe Work Australia. So, this template is correct and will help with your safety in the work place, as it comes from the horses mouth.

Now that you have a safe work method statement template free to download you are going to have to fill it out. The purpose of a SWMS is a set of work safety instructions that construction workers use for their personal safety at work. Traditionally this has been a paper-based process that workers are not particularly good at filling out. They could for example, fill them out after the job or even worse not at all. This is a huge contributor to health and safety problems in the workplace. Firstly, the construction worker is risking their own lives by not refreshing themselves with safety work instructions. Secondly, if an incident does occur the business is in a huge hole that they don’t want to be in. The good news is that there is a way to help with this process!

The solution is to tech-up! At SafeWorkPro we believe in getting workers on the job quicker, safer and compliant. By using technology a construction sites safety can be streamlined and construction work hazards can be reduced. The construction industry has been using tools for hundreds of years and the modern era has bought us yet another powerful tool, yup its in your pocket and everyone has got one … your mobile phone. So you can use this tool to deliver SWMS’s and safety work instructions to your workers and use dashboards to to see how your team in performing. Why wouldn’t you?

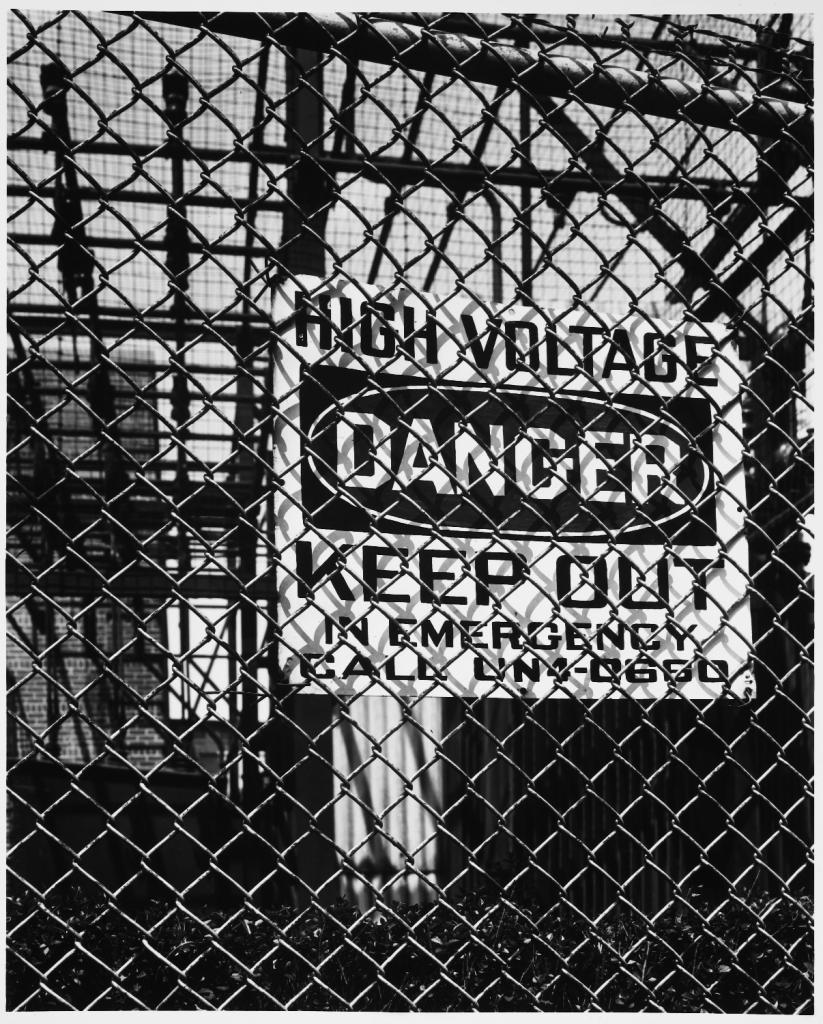

Electrical Safety in the Workplace: the story of Tim Martin

Tim Martin was one life cut shot by unsafe working methods.

Speaking at a Safe Work Australia Month event in Brisbane, Tim’s father Bill Martin, spoke of his son’s cheeky friendliness and bright potential. At the age of 17, Tim was only a second year electrical apprentice when he was tragically killed by overhead power lines.

Simple safety measures could have prevented this incident. In 1999, Tim was operating an elevated work platform when he came too close to high voltage power lines. A huge electrical current arched across the gap between the platform and the wires, electrocuting Tim and leaving him with severe burns to most of his body. Barely a month later, Tim died in the intensive care unit of a Brisbane hospital.

The unfortunate fact is that Tim’s tragic death is not an isolated incident. Approximately four people are killed in electrical incidents every year and more than 3000 workplace accidents are reported to the Electrical Safety Office in that same time period. These figures are a result of poor safe work habits. In the case of Tim’s death, several mistakes were made:

- The vehicle Tim operated was parked in an exclusion zone

- The correct personal protective equipment (PPE) was not used

- As an apprentice, Tim was too inexperienced to operate the elevated work platform within close proximity to overhead power lines

- Tim’s supervisor was not properly observing the high risk work being conducted

In his speech to a Safe Work Month event, Bill Martin spoke of a culture in the electrical industry that normalises close calls with electrical work hazards. Terms like ‘getting zapped’ or ‘feeling a belt’ serve only to downplay the inherent risks that come with electrical work. In turn, this leads a safety culture not fully equipped to prevent the worst case scenario.

“Safety is about relationships, not rules.”- Bill Martin.

between various stakeholders when it needs to be the most. In the case of Tim, the required PPE and insulation gear was not worn because the need for it was not properly communicated. As Bill Martin said, “safety has got to be embedded into the DNA of a business.” Such an approach could very well ensure all levels of an organisation are aware of their responsibilities and roles – a goal that paperwork and risk assessments cannot achieve on their own.

When we witness the heartache and pain caused by the loss of life – especially that of a young worker – the seriousness of not just electrical safety but safe work practices more generally, becomes clear. Bill Martin’s speech emphasised a different way to think about work safe procedures. Rather than approach it as a series of forms needing to be completed, Bill promoted a view that holds safety as just another aspect of work.

For more information, you can watch Tim’s story here. If you would like more details on Safe Work Australia Month 2014, visit their website.