How a Simple Process Drives Safety Compliance

Safety management systems have come a long way in the last 250 years. Just think back to workplace conditions during the Industrial Revolution – almost no pay, child labour, very long hours, and extremely dangerous work conditions with exposure to chemicals, accident-prone machinery, and no WHS requirements whatsoever.

But this has changed over the years. Legal reforms and acts were introduced – the Factory Act, the Employer’s Liability Act, and finally, the 1974 Health and Safety at Work Act. This legal document became the foundation for workplace health and safety processes in the UK and the rest of the world. And it led to the increasingly more complex safety processes we have today.

The core purpose of WHS is to keep people safe. Simple. With the increasing complexity of requirements and standards, Business owners, project managers and safety officers alike have to be careful of falling into the trap of using compliance to document requirements like the SWMS as their main measure of WHS compliance. This article looks at why adhering to document requirements is a poor standalone indicator of compliance. We also suggest how a simple safety process drives the success of your WHS compliance.

Documents are Symbols of a Process

Safety isn’t symbolic. It is real and should be treated in the real world, not on a document. Safety management systems do involve documents, but they symbolise a process. For example, a SWMS is a safety planning tool that identifies the risks of high risk construction work and the actions taken to manage those risks. It symbolises the process you are going to take when dealing with the risks and making sure your workplace and its workers are safe from those risks. When it’s under the (judges) hammer, the process symbolised (documented) matters most – not the symbol or the document itself.

Downloading a generic template for your SWMS, JSA, or any other safety document is like taking the symbol without taking the process it represents. And that defeats the whole point of your safety management system and its documents. To comply with WHS requirements, you should be focusing on the processes required to keep your workplace and its workers safe – not just on the documents themselves.

WHS audits look at whether you have followed an effective process that actively reduces the risks in your workplace. They care about if you have actually provided a safe work environment. Not simply whether you have ticked the box of completing a piece of paperwork.

In 2013, The Supreme Court Qld in a case against a QLD construction company for the death of two workers cited:

“work practices focused too much on the work performed onsite and did not pay adequate attention to the dangers presented by the conditions of the site itself”

In other words, not considering risks on the ground, in the real world can have significant impacts when taken to the extremes. Focussing too hard on the details of the tasks to be completed can lead to ignoring all the risks that are actively present

What you focus on matters. And if you want to pass your WHS audit and actually keep your workers safe, then it’s time to focus on the safety management process behind the symbols and documents.

But I still go through a process when filling in a template?

Safety management systems aren’t just about the symbols. They’re about the processes behind them. But you may be wondering – isn’t downloading a generic template still technically a process? Sure. But think about this. What process is more effective at satisfying the Work Health and Safety Act requirement to provide a safe work environment? Is it:

- Find a generic SWMS template on Google, Officeworks or other source

- Complete the boxes provided by the template as best as you can

- Gather up or seek out workers individually and gather signatures

- Store it onsite until the work is done

- Transferring the document to a folder in your office when you are done with the site

Or:

- Identify a the risks onsite, in person

- Build a new SWMS or modify the existing version to cover all task & site-specific risks that are present. Pushed to everyone to sign.

- Monitor how measures are being implemented while work is being completed with real time automated risk rating notifications

- Review by anyone relevant once the work has been completed

- Automatic document storage once complete for any future audits, follow-ups, or learning

From a legal standpoint, the second option is better,

The very purpose of developing a SWMS is to ensure that employers and workers have taken the time to identify the high-risk tasks to be done on site. And then, it is to develop measures to manage these risks and tasks in the context of the work being done. The very nature of a SWMS is that it is specific. It is created specifically in response to a specific site, specific tasks, and specific risks. A generic templated SWMS will not meet the intention behind WHS requirements. Instead, it will defeat the real power of the SWMS and even take away from your safety management.

As WorkSafe Victoria explains, “our concern is not what is written but what actually happens”. A generic SWMS is a symbol of safety that only provides guidance. To focus on the process and comply with WHS requirements, your SWMS and other safety documents need to be customised. It is the second process that is more likely to pass a WHS audit because it demonstrates an active approach to creating a safe work environment. And it is the first process that will get a much more severe punishment when a safety incident does happen, even though both processes are represented by the same type of document.

How to Prioritize the Process

The simplest way to boost the effectiveness of your safety process is to use a digital safety platform like SafeWorkPro. While you can do your safety management physically or digitally, doing it digitally is what will make the difference. Why?

Safety management software simplifies your safety management. Turning a complex process into a simple, easy to understand workflow that allows for an easier way to assess, mitigate, monitor and review workplace risks of all nature. It makes sure that your safety management system is customised, comprehensive, and lets you focus on the process. Leave the document creation, distribution and storage to the software. With safety management software, you can seamlessly customise, prioritise, and ensure your safety management system and its processes exceed WHS regulations.

SafeWorkPro is the Australian safety management software that can make sure your workplace prioritises the process over the symbols.

- Customise your SWMS, JSA, or other safety documents specifically to your worksite using our flexible document builder

- Make sure your specific workplace risks are managed and your workers are safe

- Ensure your company truly complies with WHS requirements

Do all of this seamlessly and in one place with the SafeWorkPro platform. Click the button below to find out more.

More From The SafeWorkPro Blog

It’s Time To Get Serious About Health and Safety in Australia

Workplace safety issues are not always at the top of people’s priorities. Often left to the last minute or delegated down, occupational health and safety is seen as the last kid you’d pick in the schoolyard footy team. Yet with the right amount of teamwork and training, that kid could very well score the game-winning try.

Knowing how to provide a safe working environment means more than workplace safety training and toolbox talks. In the midst of multiple risk assessment forms and red tape, it is all too easy to forget that safety is about people not paperwork. A person conducting a business or undertaking (PCBU) is responsible for the health and safety standards of any workplace or worksite, but the buck does not stop there. Safework is something everyone needs to practice.

A strong health and safety program is one that encompasses all levels of a business in way that encourages communication and consultation between workers and employers. Risk assessments and other forms of risk management are indeed important factors but they alone cannot account for the diverse range of safety hazards facing all types of businesses. This causes problems because if risk assessments alone cannot provide the solutions people need, then they will attempt to solve OHS problems themselves. Without proper supervision this leads to unsafe work practices.

So where does that leave the occupational health and safety kid in our imagined schoolyard footy team?

The team can either involve this kid in their training regime, finding out what position best suits his level of talent and employing his skill set where it’s needed most. Or the team can simply leave the kid out in the backs and hope he doesn’t cause too much damage. One of these options has clear long-term benefits for the footy team. With the other option, it is just a matter of time before someone slips through the defences.

How can safety improve productivity?

There are many answers to this question depending on what industry you ask, but for construction workers the solution is quite clear. SafeWorkPro offers a streamlined, automated digital alternative to the traditional paper based method of risk assessment. It’s a simple mobile tool that will help turn the kid everyone picked last for footy into the fastest and strongest player on the field.

So why not try SafeWorkPro for yourself? You can sign up for a free trial today!

How to Write a Risk Assessment

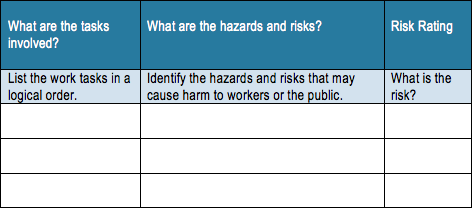

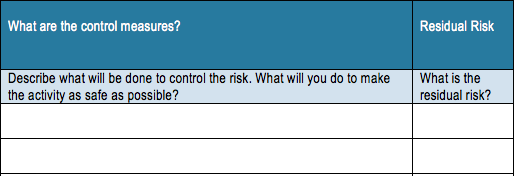

It seems like a straightforward process but risk assessments are a crucial part of displaying compliance with OHS laws and regulations. Without risk assessment forms there is no way for the relevant workplace health and safety regulator to determine if you have even attempted to maintain compliant OHS standards. Free risk assessment templates will give you a broad idea of what blank risk assessment forms look like but they won’t do the job for you. Knowing how to perform a risk assessment is relatively straight forward but getting it right involves several steps.

1: Hazard and Risk Identification

Risk assessments in the workplace should identify hazards through:

- Simple observation

- Consultation with workers and trade unions

- Checking the manufacturer’s instructions for equipment safety

- Reviewing accident and health/safety records

2: Identify who could be harmed

3: Decide on a risk assessment plan

Implement a risk management process that either eliminates the identified hazards or controls them within reasonable practice. This can be achieved by:

- Eliminating the hazards all together (level 1 risk control)

- Minimising the risks by isolating the associated risk or substituting it with a lower risk (level 2 risk control)

- Reducing risks by implementing behavioural and administrative controls, and by using personal protective equipment (level 3 risk control)

For more information on risk assessment plans, read about the risk management framework.

4: Record the findings on a risk assessment form

- To be compliant with OHS legislation Australia, specifically the WHS Act, risk assessments forms must be completed and signed by all duty holders (anyone with access to the worksite).

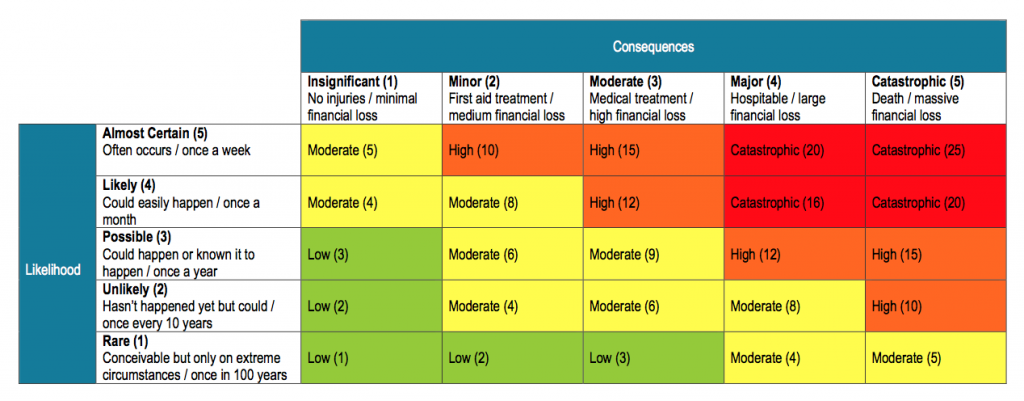

- Refer to the risk assessment matrix to gauge a numerical value on the hazards and the associated risks (see risk assessment matrix example below)

5: Review the risk analysis report

For more information, SafeWorkPro provides various risk assessment templates as well as other health and safety risk assessment forms. But ultimately risk assessment paperwork is time consuming and does not help you improve productivity. Risk assessment software streamlines this entire process into one simple tool available for download today. You can learn more about SafeWorkPro here.

Free Risk Assessment Software: what’s the catch?

In the risk management process, you get what you pay for and although the idea of free risk assessment software seems attractive, you should consider a few factors before signing up. Quality risk assessment software should make the risk management process easier, not add another bureaucratic layer. Luckily for you, we know just the type.

Completing a construction risk assessment form to the standards of Safe Work Australia can be achieved quickly through automated risk assessment tools like SafeWorkPro. Risk identification, safe work method statements and risk assessment matrices are all streamlined into one simple tool available on any smart phone or tablet device. As the dangers of high risk construction work change so too do risk assessments in the workplace. But whereas generic risk assessment forms fail to adapt to these changes, risk assessment software was designed specifically to do just that. This in turn will mean less time is spent searching for the proper paperwork and more time spent getting the job done.

At SafeWorkPro we’ve consulted directly with contractors and calculated just how much time risk assessment software can save you. To back up our claim, we’re offering a trial risk assessment software free download period. You can try our construction safety software without any commitment, and experience first hand just how beneficial it is for your workflow. SafeWorkPro’s construction safety software is an investment that will save you time in the risk assessment process and improve safety standards.